Wall thickness for caps up to and including 36” conform to ANSI B36.10 specifications. Caps 38” and larger conform to XS specifications for wall thickness of 36”. These are Wellgrow’s standards as no internationally recognized standards have been set for such large size wall thickness.

- The shape of these caps shall be ellipsoidal and shall conform to the shape requirements as given in the ASME boiler and pressure vessel code.

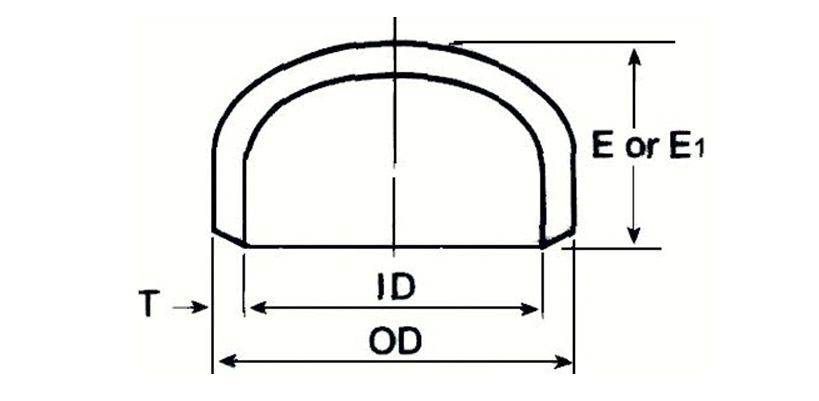

- Length E applies for thickness not exceeding that given in column “limiting wall thickness for length E”.

- Length E1 applies for thickness greater than that given in column “limiting wall thickness” for NPS 24 and smaller. For NPS 26 and larger, length E1 shall be by agreement between manufacturer and purchaser.

Material: Carbon steel (ASTM A234WPS, A234WPC, A420 WPL6),(ST45.8 A105 A106 STG42)

Alloy steel(ASTM A234 WP12/WP11/WP22/WP5/WP9/WP91)

Stainless steel(ASTM A403 WP304/WP304L/WP316/WP316L)

Standard: ASME/ANSI B16.9, DIN2650,2615,2616,2617,JIS B2311, 2312,2313, EN 10253-11, EN10253-2, GB

Size: 1/2”—48”

Thickness: SCH10,SCH20,SCH30,SCH STD, SCH40, SCH60,SCH XS, SCH80, SCH100, SCH120,SCH140,SCH160,SCH XXS

| Nominal Pipe Size | Outside Diameter at Bevel | Length (2) | Limiting Wall Thickness for Length | Length (3) |

| (NPS) | D | E | E | E1 |

| 1/2 | 21.3 | 25.4 | 4.6 | 25.4 |

| 3/4 | 26.7 | 25.4 | 3.8 | 25.4 |

| 1 | 33.4 | 38.1 | 4.6 | 38.1 |

| 1-1/4 | 42.2 | 38.1 | 4.8 | 38.1 |

| 1-1/2 | 48.3 | 38.1 | 5.1 | 38.1 |

| 2 | 60.3 | 38.1 | 5.6 | 44.4 |

| 2-1/2 | 73.0 | 38.1 | 7.1 | 50.8 |

| 3 | 88.9 | 50.8 | 7.6 | 63.5 |

| 3-1/2 | 101.6 | 63.5 | 8.1 | 76.2 |

| 4 | 114.3 | 63.5 | 8.6 | 76.2 |

| 5 | 141.3 | 76.2 | 9.7 | 88.9 |

| 6 | 168.3 | 88.9 | 10.9 | 101.6 |

| 8 | 219.1 | 101.6 | 12.7 | 127.0 |

| 10 | 273.1 | 127.0 | 12.7 | 152.4 |

| 12 | 323.9 | 152.4 | 12.7 | 177.8 |

| 14 | 355.6 | 165.1 | 12.7 | 190.5 |

| 16 | 406.4 | 177.8 | 12.7 | 203.2 |

| 18 | 457.2 | 203.2 | 12.7 | 228.6 |

| 20 | 508.0 | 228.6 | 12.7 | 254.0 |

| 22 | 558.8 | 254.0 | 12.7 | 254.0 |

| 24 | 609.6 | 266.7 | 12.7 | 304.8 |

| 26 | 660.4 | 266.7 | ||

| 28 | 711.2 | 266.7 | ||

| 30 | 762.0 | 266.7 | ||

| 32 | 812.8 | 266.7 | ||

| 34 | 863.6 | 266.7 | ||

| 36 | 914.4 | 266.7 | ||

| 38 | 965.2 | 304.8 | ||

| 40 | 1016.0 | 304.8 | ||

| 42 | 1066.8 | 304.8 | ||

| 44 | 1117.6 | 342.9 | ||

| 46 | 1168.4 | 342.9 | ||

| 48 | 1219.2 | 342.9 |

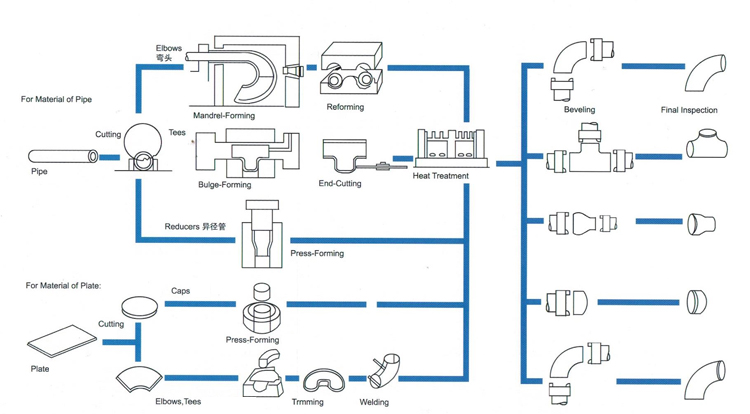

Production process: