| Name | Elbow | |

| Size | Seamless(SMLS) Elbows : 1/2″-24″ ,DN15-DN600

Butt Welded Elbows (seam) :24”-96″,DN600-DN1800 |

|

| Type | LR 30,45,60,90,180 degree SR 30,45,60,90,180 degree

1.0D, 1.5D, 2.0D, 2.5D, 3D,4D,5D,6D,7D-40D. |

|

| Thickness | SCH10,SCH20,SCH30,STD SCH40, SCH60, XS, SCH80., SCH100, SCH120, SCH140, SCH160, XXS | |

| Standard | ASME,ANSI B16.9; | |

| DIN2605,2615,2616,2617, | ||

| JIS B2311,2312,2313; | ||

| EN 10253-1 ,EN 10253-2 | ||

| Material | ASTM | Carbon steel:ASTM A234WPB,,A234WPC,A420WPL6,A420WPL3

MSS SP75 WPHY42/46/52/56/60/65/70 |

| Stainless steel:ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect. | ||

| Alloy Steel:A234WP12,A234WP11,A234WP22,A234WP5,A420WPL6, | ||

| DIN | Carbon steel:St37.0,St35.8,St45.8 | |

| Stainless steel:1.4301,1.4306,1.4401,1.4571 | ||

| Alloy steel:1.7335,1.7380,1.0488(1.0566) | ||

| JIS | Carbon steel:PG370,PT410 | |

| Stainless steel:SUS304,SUS304L,SUS316,SUS316L,SUS321 | ||

| Alloy steel:PA22,PA23,PA24,PA25,PL380 | ||

| GB | 10#,20#,20G,23g,20R,Q235,16Mn, 16MnR,1Cr5Mo,12CrMo, 12CrMoG, 12Cr1Mo | |

Surface treatment: Transparent oil, rust-proof blackoil or hot galvanized

Packing: In wooded casesor pallets, or as for clients’ requirements

Applications: Petroleum, chemical, machinery, boiler,electric power, shipbuilding, papermaking, construction, etc

Certification: API CE and ISO 9001:2008

Third part inspect: BV,SGS,etc accept

Delivery time: 7- 15 days after Purchase Order ,have stock ~

Special design : As your drawing

Test: Direct-reading Spectrograph,Hydrostatic testing machine,X-ray detector,Ultrasonic flaw detector,Magnetic particle detector,etc

Equipment: Press machine ,Bending machine,Pushing Machine,electric bevelling machine Sand-blasting machine,etc

Production experience: Manufactrure about 25 years

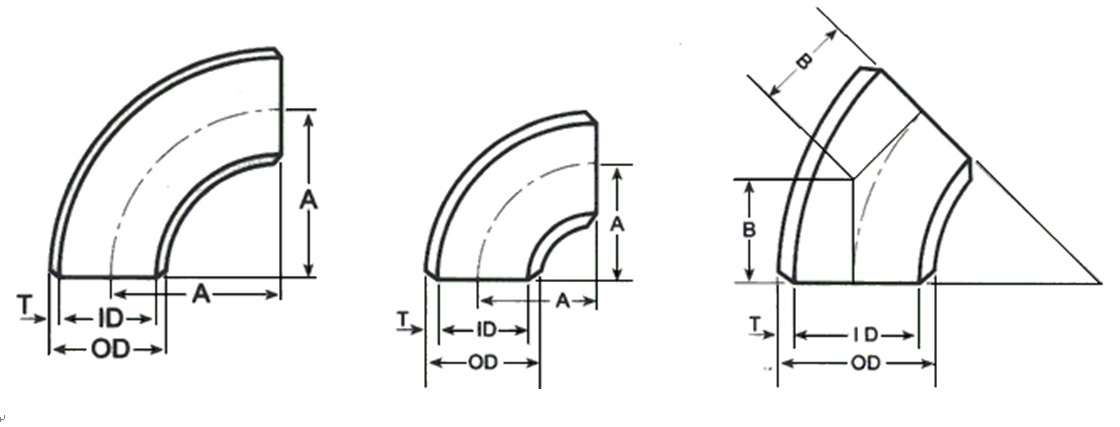

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel

D |

Center to End | |||

| Long Radius Elbows | Short Radius Elbows | ||||

| 90 degree.

A |

45 degree B | 90 degree A | 45 degree B | ||

| 1/2 | 21.3 | 38.1 | 15.7 | – | – |

| 3/4 | 26.7 | 38.1 | 19.1 | – | – |

| 1 | 33.4 | 38.1 | 22.4 | 25.4 | – |

| 1-1/4 | 42.2 | 47.8 | 25.4 | 31.8 | – |

| 1-1/2 | 48.3 | 57.2 | 28.4 | 38.1 | – |

| 2 | 60.3 | 76.2 | 35.1 | 50.8 | – |

| 2-1/2 | 73.0 | 95.2 | 44.4 | 63.5 | – |

| 3 | 88.9 | 114.3 | 50.8 | 76.2 | 31.6 |

| 3-1/2 | 101.6 | 133.4 | 57.2 | 88.9 | 36.8 |

| 4 | 114.3 | 152.4 | 63.5 | 101.6 | 42.1 |

| 5 | 141.3 | 190.5 | 79.2 | 127.0 | 52.6 |

| 6 | 168.3 | 228.6 | 95.2 | 152.4 | 63.4 |

| 8 | 219.1 | 304.8 | 127.0 | 203.2 | 84.2 |

| 10 | 273.1 | 381.0 | 158.8 | 254.0 | 105.2 |

| 12 | 323.9 | 457.2 | 190.5 | 304.8 | 126.3 |

| 14 | 355.6 | 533.4 | 222.2 | 355.6 | 147.3 |

| 16 | 406.4 | 609.6 | 254.0 | 406.4 | 168.3 |

| 18 | 457.2 | 685.8 | 285.8 | 457.2 | 189.4 |

| 20 | 508.0 | 762.0 | 317.5 | 508.0 | 210.4 |

| 22 | 558.8 | 838.2 | 342.9 | 558.8 | 231.5 |

| 24 | 609.6 | 914.4 | 381.0 | 609.6 | 252.5 |

| 26 | 660.4 | 990.6 | 406.4 | 660.4 | 273.5 |

| 28 | 711.2 | 1066.8 | 438.2 | 711.2 | 294.6 |

| 30 | 762.0 | 1143.0 | 469.9 | 762.0 | 315.6 |

| 32 | 812.8 | 1219.2 | 501.6 | 812.8 | 378.1 |

| 34 | 863.6 | 1295.4 | 533.4 | 863.6 | 357.7 |

| 36 | 914.4 | 1371.6 | 565.2 | 914.4 | 378.8 |

| 38 | 965.2 | 1447.8 | 599.9 | – | – |

| 40 | 1016.0 | 1524.0 | 632.0 | 1016.0 | 420.8 |

| 42 | 1066.8 | 1600.2 | 660.4 | 1066.8 | 441.9 |

| 44 | 1117.6 | 1676.4 | 695.5 | 1117.6 | 462.9 |

| 46 | 1168.4 | 1752.6 | 726.9 | – | – |

| 48 | 1219.2 | 1828.8 | 759.0 | 1219.2 | 505.0 |

| 52* | 1320.8 | – | – | 1320.8 | 547.1 |

| 54* | 1371.6 | 2057.4 | 852.2 | 1371.6 | 568.1 |

| 56* | 1422.4 | 2133.6 | 883.8 | 1422.4 | 589.2 |

| 60* | 1524.0 | 2286.0 | 946.9 | 1524.0 | 631.3 |

| 66* | 1676.4 | 2514.6 | 1041.6 | – | – |

| 68* | 1727.0 | 2591 | 1073 | 1727 | – |

| 72* | 1829.0 | 2743 | 1137 | 1829 | – |

| 76* | 1930.0 | 2896 | 1199 | 1930 | – |

| 80 | 2032.0 | 3048 | 1263 | 2032 | – |

Fittings :

A234 = This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction.

A420 = Standard specification for piping fittings of wrought carbon steel and alloy steel for low-temperature service.

A403 = Standard specification for wrought austenitic stainless steel piping fittings.

Carbon Steel Buttweld Elbow (Bend) 180 Deg Range SCH40/ SCH80 ASTM A234 WPB ANSI B16.9

GO Industrial offers a range of Carbon Buttweld fittings in 90º and 45º Elbows, Concentric and Eccentric Reducers, End Caps, Stainless Steel Equal and Reducing Tees, Flanges, Stub Ends and Weld On Collars.

What is a Buttweld Fitting?

- A butt weld pipe fitting is designed to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

- This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances.

- Other types of fittings can be threaded or socket welded.

What are the advantages of Buttwelding over Flanges?

- Flanges connect pipes by bolting them together, whereas butt weld fittings connect pipes by welding them together.

- Depending on size, butt weld fittings require 10% to 75% less material than a flanged connection, which means lower material cost and lower weight.

- Welded construction permits greater freedom in designing a layout; this system uses less space, is more compact, and has greater strength.

- Butt weld fittings provide optimum flow characteristics, without pockets or sharp corners, creating less frictional resistance, no pressure loss, less turbulence, …

How are Pipe Fittings Measured?

- Pipe fittings are measured by their diameter, wall thickness (known as “schedule”), and shape or configuration. (Fittings are also defined by their material grade and whether they are welded or seamless.)

- Diameter refers to outside diameter of a pipe or fitting.

- The North American standard is known as Nominal Pipe Size (NPS). The International Standard is known as Diameter Nominal (DN). Pipes and fittings are actually made in similar sizes around the world: they are just labeled differently.

- From ½ in to 12 inch “Nominal Pipe Size”, outside diameters are slightly larger than indicated size; inside diameters get smaller as schedules grow.

- From 14 in and larger “Nominal Pipe Size”, outside diameters are exactly as indicated size; inside diameters get smaller as schedules grow.

- As with other North American standards (inch, foot, yard, mile, …), many pipe standards (diameters up to 12 inch and wall thickness) are based on historical precedents (a toolmaker’s dies during US Civil War) rather than a “scientific” method.

What does Schedule Mean for Pipe Fittings?

- Schedule, often shortened as sch, is a North American standard that refers to wall thickness of a pipe or pipe fitting. Higher schedules mean thicker walls that can resist higher pressures.

- Pipe standards define these wall thicknesses: SCH 5, 5S, 10, 10S, 20, 30, 40, 40S, 60, 80, 80S, 100, 120, 140, 160, STD, XS and XXS. (S following a number is for stainless steel. Sizes without an S are for carbon steel.)

- Higher schedules are heavier, require more material and are therefore more costly to make and install.