Taichan Concrete pump pipes are created with good raw materials from domestic high-quality suppliers. The production line is complete and every process has been strictly inspected and controlled. After processed by most advanced Equipment and Technology, our pipes are in high quality and perfect performance.

Concrete pump pipe is a spare part of concrete pump truck and concrete pumps. It improves the efficiency of construction, increased nearly a hundred times in concrete placement. It is also called Concrete Straight Pipe. Concrete Pump pipe is generally divided into DN80, DN125 and DN150. DN80 pipe is mainly for sand blasting; DN125 and DN150 are mainly for concrete delivery. Both have high pressure and low pressure types.

General Description of Concrete Pump Pipe with different materials and sizes we supply:

- Welded Concrete Pump Pipe

- ST52 Concrete Pump Pipe

- Hardened Concrete Pump Pipe

- Twin Wall Concrete Pump Pipe

Concrete Pump Boom Pipe fitting specifications:

- Material: ST52, 45Mn2, 55Mn, Q235, 20# steel, 37Mn5 etc.

- Sizes: DN80-DN150 (mm unit),generally 125mm

- Length: 1m,2m,3m, 6m or according to clients’ requirements

- Thickness: 4-8mm

- Packing: Standard Package or waterproof plastic film and ends

Flange model would be a little different from country to country. End flange for DN125mm concrete pump pipe:

- Standard SK148mm, apply for Multiple brands concrete pump and countries.

- HD157mm flange. Mostly used in USA, MEXICO, CANADA.

- MF166mm flange. Mostly used for Schwing concrete pump. apply for India, Malaysia, Sri Lanka.

- ZX175mm flange. Mostly used for Putzmeister concrete pump, Apply for India.

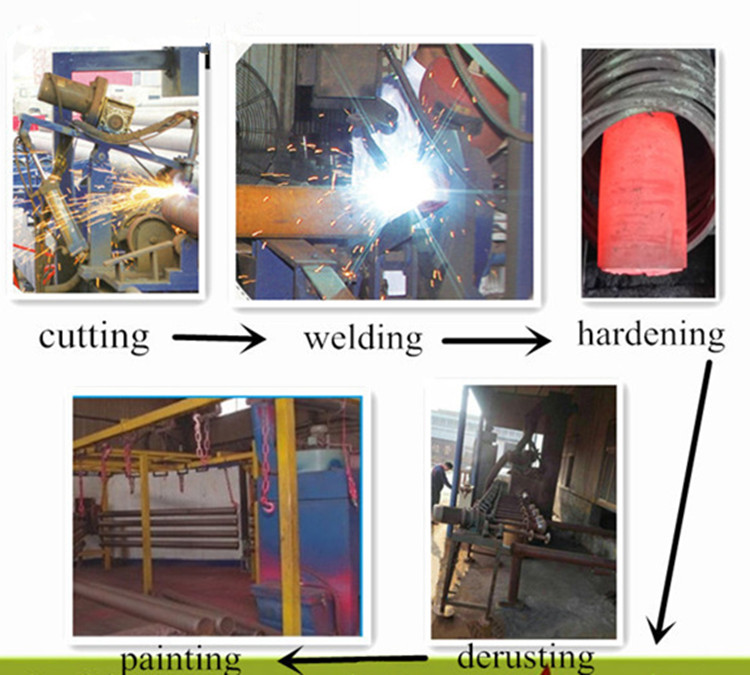

concrete pump pipe production process:

Concrete pump pipe fitting advantages:

- safe

The outlet of it is made of high strength low alloy material and its tensile strength is over 600MPa and hydrostatic test pressure is over 24MPa. Its safety factor is over 2.5, which is much higher than the domestic industry standards. We promise 100% non-exploding in the standard working pressure and guarantee high abrasion resistant with safety .

- More Endurance

The inner of our products is made of imported alloy steel tube with Cep> 0.75%,characterized by high carbon, high alloy, high precision, and material wall thick well-proportioned. We can promise the average concrete conveying amount is more than 30000 cubic meters .

- Economical

Compared with the single pipes and ceramic pipes ,our twin-wall pipes is money saving .Using our pipes can greatly reduce the frequency of repairing and replacing, and put an end to the extra compensation and legal disputes because of sudden pipes exploding, which can also reduce the cost up to 30%-50%.

- Reliable

Production lines are all automatically equipped ,including automatic cutting machine ,automatic welding machine, automatic heat treatment equipment and automatic continuous sand blasting and spray machine.