- Lifetime: Our hoses be able to use 25,000 cubic meter compared with normal quality of 12,000-15,000 cubic meters in china

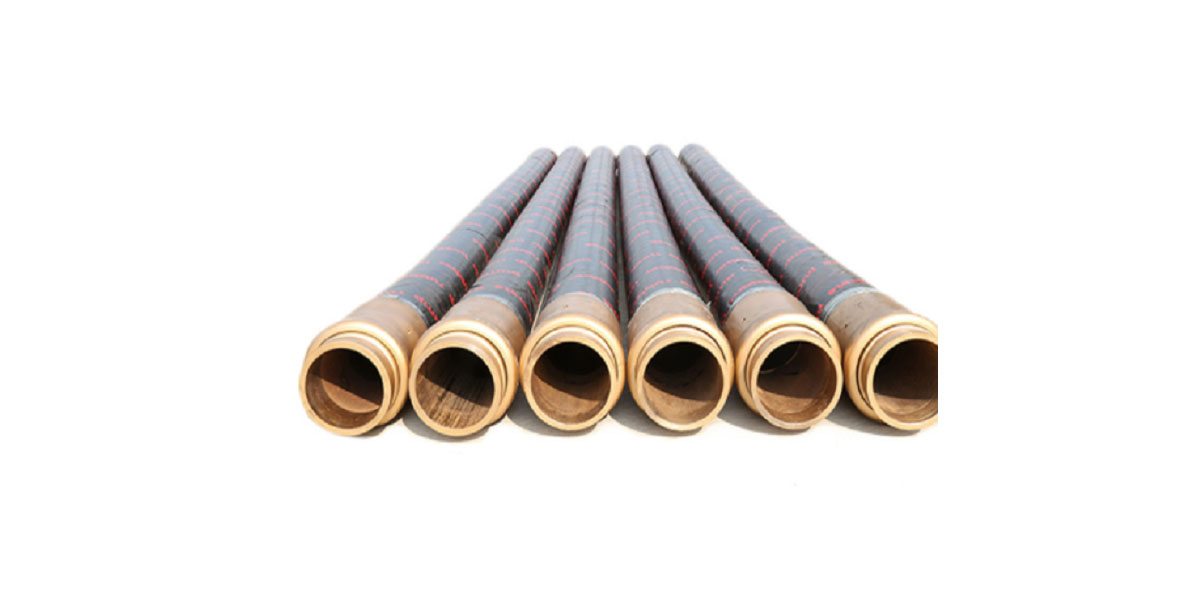

- Integrated hose end and inner wall hardened, prolong working life

- Reinforcement: 4 layers steel wire, 2 layers steel wire, 4/6 layers fabric

- Hose ends: galvanized or painted

[concrete pump rubber hose use]

Applicable to high-rise buildings, roads, tunnels, water conservancy projects, nuclear power plants and other construction machinery, concrete pump trucks and other rubber hoses.

[Scope of concrete pump flexible hose application]

The tail of the pump transports the concrete to the pouring position and resists suction during cleaning. It is usually equipped with a buckled hardened joint.

【temperature range】

-40°C to +70°C

[product structure] inner rubber layer, reinforcing layer, outer rubber layer

1. Inner rubber: Polyurethane and butyl rubber are used as the main raw materials, and special reinforcing agent is added to make the rubber compound. The inner rubber color of the finished product is black and transparent. It has the characteristics of high wear resistance, high toughness, high pressure resistance and smoothness. It can resist the friction of concrete. The inner rubber layer has the function of subjecting the conveying medium to pressure and protecting the steel wire from erosion.

2, reinforcement layer: 4 layers of steel wire winding, special copper wire braided with copper-plated hose, withstand working pressure is 3-4 times that of ordinary hose, with high pressure resistance, superior flexural resistance, and enhance.

3, external glue: black, smooth (surface cloth), SBR / NR compound, anti-aging, wear-resistant.

[Material of concrete pump flexible hose]

Natural rubber + steel wire weaving

[Use pressure technical parameters]

1. 125A common type The use pressure should not exceed 4MPa, the bending radius should not be less than 1M, and each should not be lower than normal use.

The conveying capacity of 10,000 cubic meters of concrete.

Second, 150A ordinary type The use pressure should not exceed 3.5MPa, the bending radius is not less than 1M, and the conveying capacity of each concrete is not less than 10000 cubic meters in normal use.

3. The pressure of 125AB high-pressure steel curtain shall not exceed 10MPa, the bending radius shall not be less than 1M, and the conveying capacity of each concrete shall not be less than 12000 cubic meters in normal use. 4. The pressure of 150AB high-pressure steel curtain shall not exceed 9.5MPa, the bending radius shall not be less than 1M, and the conveying capacity of each concrete shall not be less than 12000 cubic meters in normal use.

| Name | Concrete Pump Rubber hose | ||||

| Size | DN125(5″), DN100(4″) | ||||

| Length | 3000mm,4000mm,5000mm,6000mm | ||||

| Reinforment | Three plies of Steel Wire | ||||

| Hose Ends | 148mm, 127mm | ||||

| Working Pressure | 85bar | ||||

| Burst Pressure | 250bar | ||||

| Application Capacity | 20,000cubic meters | ||||

| Hode Ends | Galvanized or painting | ||||

| Application Pump Truck | Schwing , Putzmeister , Kyokuto,etc. | ||||

concrete pump hose, Putzmeister concrete pump rubber hose